-

Sarah zheng

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah zheng

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Surface treatment of stainless steel for export

2025-07-18 15:43:38

In the stainless steel export sector, surface treatment processes play a decisive role in determining product functionality, design aesthetics, and durability. This article will focus on analyzing common surface treatment techniques used in the stainless steel export market, including gold-plated titanium, 8K,7K, polishing, and matte finishes.

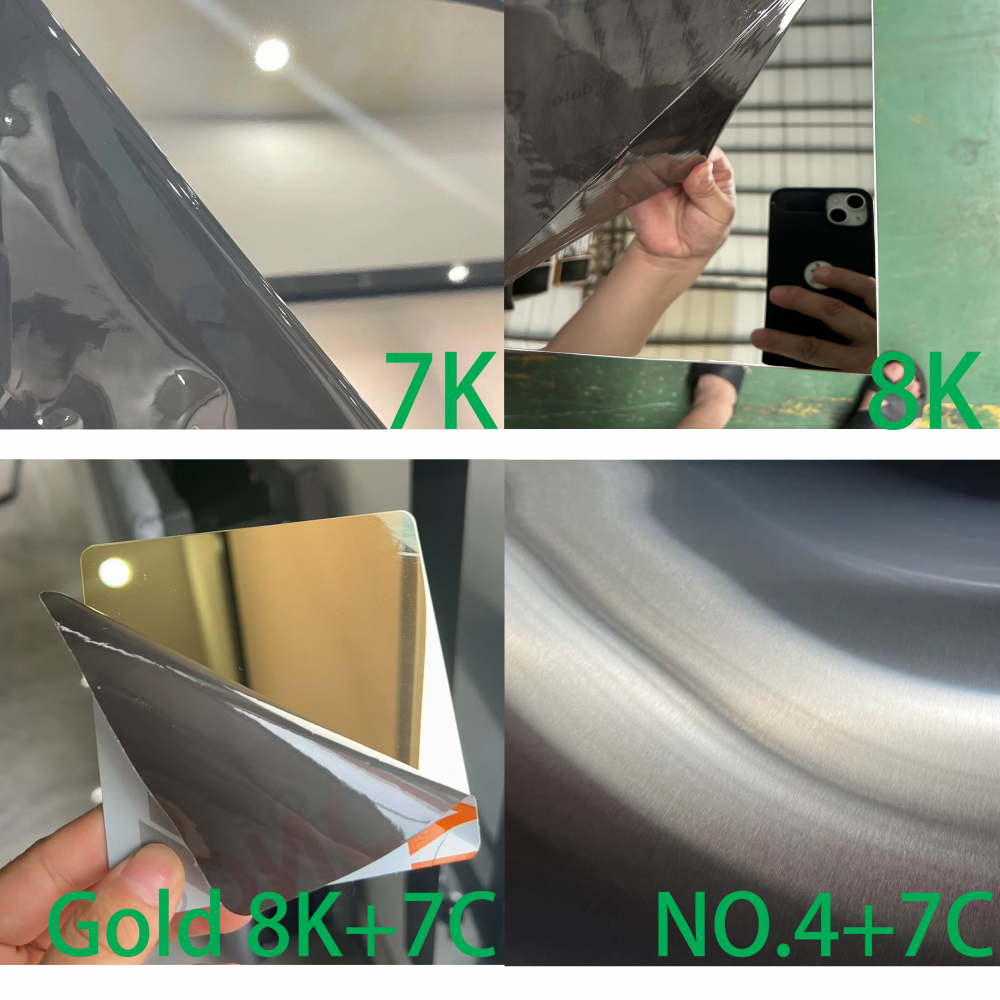

1. Gold 8K+7C

Yellow titanium gold plating stands as a premium choice for enhancing the luxurious elegance of stainless steel products. Widely used in high-end architecture, this material is commonly found in hotel lobbies, luxury residences, and commercial buildings. It also finds applications in crafting jewelry, watches, and home decor items. With its warm, rich color tone that infuses projects with opulent sophistication, yellow titanium gold has become the go-to material for designers and architects.

2.8K

The 8K mirror polishing process stands as the gold standard in stainless steel surface treatment, setting industry benchmarks for gloss and reflective performance. This multi-stage polishing technique employs progressively finer grinding materials to eliminate surface imperfections, ultimately achieving a mirror-like finish. The treated surface can achieve up to 8K reflectivity, perfectly matching the visual quality of standard mirrors. Additionally, the 8K polishing process demonstrates exceptional corrosion resistance, making it ideal for harsh industrial environments.

3.7K

The 7K polishing process shares similarities with 8K polishing but features a slightly lower reflectivity. This technique strikes an excellent balance between aesthetic appeal and practicality, maintaining high glossiness and smooth texture while being easy to maintain daily. Widely used in bathroom fixtures, furniture manufacturing, and automotive parts production, its exceptional corrosion resistance makes it suitable for various indoor and outdoor applications.

4. NO.4+7C

Silky matte surface treatment is a popular choice for pursuing delicate texture. The silky matte surface has strong anti-fingerprint and stain resistance, which is widely used in kitchen appliances, bathroom equipment and furniture manufacturing. It not only has excellent corrosion resistance, but also can perfectly adapt to various indoor and outdoor environments.

In summary, surface treatment processes significantly influence the functional performance, visual texture, and durability of stainless steel products. With options ranging fromGo1d 8K+7C, 8K and 7K to polished and matte treatments, we have solutions for both luxurious high-gloss effects and delicate textural finishes. Should you require any specific surface treatment, feel free to contact us at any time.

Tags: Gold 8K+7C, 8K, NO.4+7C